HYDROGEN POWERED VEHICLES ENGINEERED TO UNLOCK THE POTENTIAL OF COMMERCIAL AND MASS PASSENGER TRANSPORTATION

FUEL CELL

Like batteries, fuel cells function but do not need to be recharged or run down. They generate heat and electricity as long as fuel is available. Two electrodes—a negative electrode (also known as the anode) and a positive electrode (also known as the cathode)—sandwiched around an electrolyte make up a fuel cell. The anode receives a fuel, such as hydrogen, while the cathode receives air. A catalyst divides hydrogen atoms into protons and electrons in a polymer electrolyte membrane fuel cell, which travel in different directions to the cathode. An external circuit is traversed by the electrons, causing an electricity flow. When the protons reach the cathode through the electrolyte, they reunite with the electrons and oxygen to create heat and water.

PEM Fuel Cells, use a proton-conducting polymer membrane as the electrolyte. Hydrogen is typically used as the fuel. These cells operate at relatively low temperatures and can quickly vary their output to meet shifting power demands. PEM fuel cells are the best candidates for powering automobiles.

BATTERY

All-solid-state batteries promise greater energy storage density, increased reliability and wear resistance, fast charging, and, most importantly, improved operational safety. Liquid electrolytes become volatile and combustible at high temperatures. However, the risk of fire or explosion is reduced by the excellent thermal stability of solid electrolytes.

Due to their small size, solid-state batteries have a higher energy density per unit area. In comparison to a lithium-ion battery of the same size, the energy density of a solid-state battery can be up to ten times higher.

High-density solid-state batteries can reach 10,000 cycles, whereas modern lithium-ion batteries for electric vehicles typically last between 2,000 and 3,000 cycles before degrading noticeably.

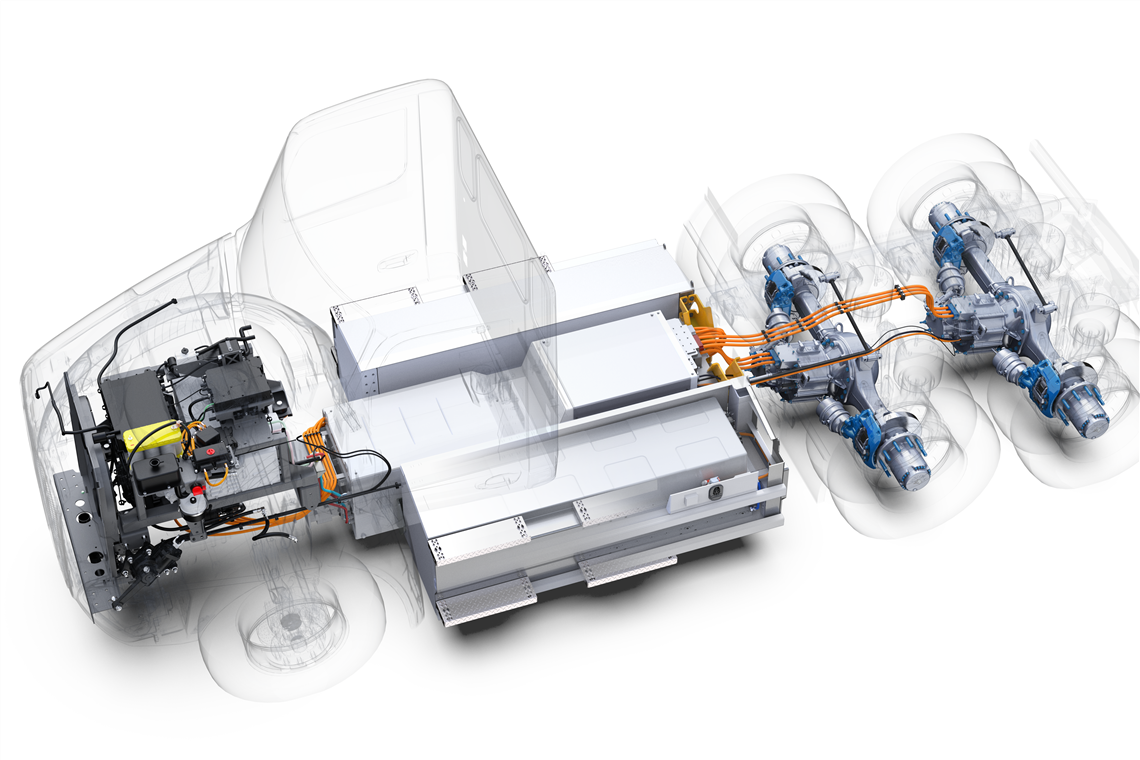

TRACTION MOTORS

Axial flux permanent magnet motors typically provide more torque for a given volume of motor than a radial motor, as the active magnetic surface area is the face of the motor’s rotor rather than the outside diameter.

Because of this, axial flux motors are significantly more compact than radial machines. This is important for applications like in-wheel motors because the axial length of the machine is substantially less. Without having to operate at extremely high speeds, the thin and light frame produces machines with higher power and torque densities than a comparable radial machine.

Axial flux motors can also be quite effective, with typical efficiencies exceeding 96%. This is due to the one-dimensional flux path’s lower length, which is on par with or superior to the best 2D radial flux motors now available.

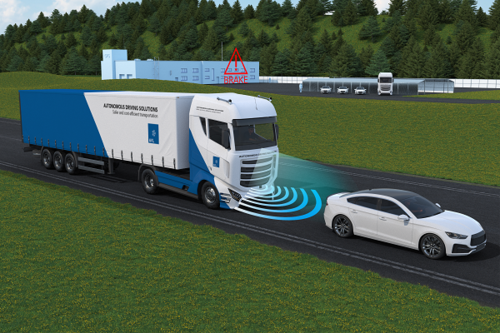

ADAS

Vehicle accidents are almost always the result of human error, which can be prevented with advanced driver assistance systems (ADAS). The purpose of ADAS is to reduce the number of car accidents and the seriousness of those that cannot be prevented in order to prevent deaths and injuries.

Essential safety-critical ADAS applications include:

- Pedestrian detection/avoidance

- Lane departure warning/correction

- Traffic sign recognition

- Automatic emergency braking

- Blind spot detection

The effectiveness of ADAS applications depends on these life-saving systems. They use several

vision-based algorithms and the most recent interface standards to support real-time multimedia,

vision co processing, and sensor fusion subsystems.